Today I, with help from my mom, turned 5 gallons of apple juice into a yeasty, sugary concoction that will hopefully turn into wine.

First, and most important step is sanitation.

Sanitizing solution simply needs to be in contact with whatever you’re using, including your hands and workspace, for a few minutes (we used five just to be safe), and there’s no need to rinse. Even contact with the foam sanitizes!

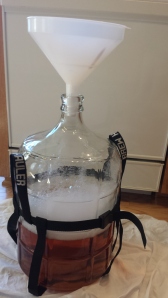

I’m rolling the fermentation jug in order to ensure the solution to come into contact with the entire inside of the jug. Having the additional harness with handles makes life a lot easier, especially when carrying the jug from the kitchen to the basement.

After sanitizing, I began mixing 2 pounds of corn sugar (dextrose) with the apple juice and pouring it into the jug.

I measured out a pound of sugar, poured half a bottle of juice in the jug, and then poured the pound of sugar in the apple juice in order to dissolve the sugar in the juice.

After mixing the juice and the sugar, I poured it in the fermentation jug and repeated the process again with another pound of sugar.

Once the 2 gallons of juice with the sugar mixed in was in the jug, I added in the yeast nutrient followed by nearly all of the rest of the juice.

At this point I ran into my first major problem; I completely forgot about the next step. I needed to mix the juice to the point where a vortex forms for 1 to 2 minutes, and I didn’t have a small enough spoon. Part two will go into how we solved that problem, and how we discovered more during that process! Enjoy the cliffhanger, and remember that foam is your friend.